A No-Nonsense Guide to Painting Concrete

So, you want to paint some concrete? Slap a coat on the garage floor, maybe? Sounds easy. Except... it isn't. Concrete is a tricky beast, and if you don't treat it right, your beautiful new floor will peel off faster than a bad sunburn. This guide will walk you through it, no jargon allowed.

Why Concrete is a Pain to Paint

You can’t just roll paint onto concrete and call it a day. It’s a porous, chemically active material that seems to hate paint. Understanding why is the first step to getting a finish that actually lasts.

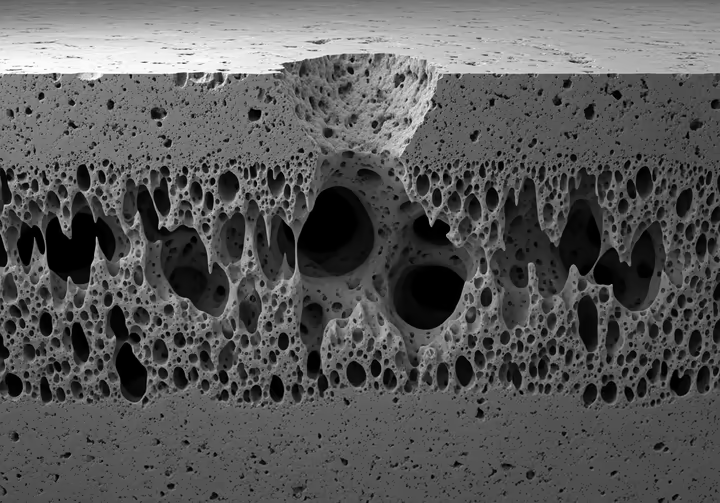

It’s Basically a Sponge

On a microscopic level, concrete isn't solid. It’s more like a hard sponge, full of tiny tunnels and pores. This happens because a lot of extra water is used to make concrete pourable, and when that water evaporates, it leaves a network of little holes behind.

When you apply paint, the concrete sponge just sucks it right up. This can leave you with a blotchy, uneven finish. A good primer and sealer are designed to fill these pores, creating a stable surface for your paint to sit on top of, not soak into.

It’s Chemically Angry

Fresh concrete is also highly alkaline. Its pH level can be as high as 13, which is about the same as drain cleaner. This harsh chemical environment can attack the paint, causing it to discolor, fade, and lose its grip.

Worst of all, this high alkalinity can cause a reaction called saponification. That’s a fancy word for when the concrete literally turns the binders in oil-based paint into soap. Yes, soap. This is why you should never, ever use a standard oil-based paint on unsealed concrete.

Concrete needs to cure for at least 30 days. During this time, it reacts with carbon dioxide in the air, which slowly lowers its pH to a more paint-friendly level.

It's Always a Bit Wet

Moisture is the number one enemy of a concrete coating. Concrete is constantly pulling moisture from the ground up through its network of pores. If you trap this moisture under a non-breathable coating like epoxy, it will form blisters and push the paint right off the floor.

It's important to know the difference between concrete curing and drying . Curing is the chemical reaction that makes it hard (about a month). Drying is the physical evaporation of excess water, which can take a month for every inch of slab thickness. That 4-inch garage slab could take four months to be dry enough for an epoxy coat.

That Annoying White Powder

Ever see a fluffy white powder on concrete or brick? That’s called efflorescence. It’s just mineral salts from inside the concrete that get carried to the surface by moisture.

The presence of this white powder is a huge red flag that you have a moisture problem. Painting over it is like painting on a pile of chalk dust, the paint will just stick to the dust, not the concrete. Even worse, the salt crystals can grow underneath your paint, physically pushing it off the surface until it cracks and flakes away.

It Moves!

Concrete isn't static, it moves. It expands a little when it gets hot and shrinks when it cools down. This movement is tiny, but it's powerful.

If you use a rigid, inflexible paint, it can’t stretch along with the concrete. This stress will eventually cause the paint to crack, flake, and peel off. That's why coatings made for concrete are designed to be flexible.

Picking Your Potion: A Guide to Coatings

"Concrete paint" is a catch-all term for a bunch of different products. Choosing the right one is about matching the product's chemistry to the job. The stuff that works on your basement wall will fail miserably on your garage floor.

Paints, Stains, and Sealers

First, the basics. These three are not the same thing.

- Paints: These form a solid, colored film on top of the concrete. They cover the surface and provide some protection.

- Stains: These are more like a dye. They soak into the concrete's pores to color it, resulting in a more natural, mottled look. They don't offer much protection and need a separate sealer on top.

- Sealers: These are mostly for protection, not looks. They seal up the pores to block out moisture and stains. Some are clear, some can give a "wet look."

Basic Paints: Acrylic and Latex

For vertical surfaces like basement walls or foundations, water-based acrylic and latex paints are the go-to. The terms are often used interchangeably, but "100% acrylic" paints are usually better.

The main advantage of acrylic paint is its flexibility, it can stretch as the concrete moves with temperature changes. This makes it great for outdoor walls. Latex paints are often cheaper, have less odor, and are fine for low-stress indoor jobs.

Just remember, neither of these is tough enough for a garage floor. They can’t handle car traffic or chemical spills.

The Tough Stuff: Epoxy Coatings

For garage floors, workshops, or any surface that needs to be super durable, epoxy is the standard. A true epoxy is a two-component system. You mix a Part A (resin) with a Part B (hardener) to start a chemical reaction that creates an incredibly hard, durable plastic film.

Water-based epoxies are the most common for DIY projects. They're easier to apply and have less odor. While much tougher than paint, they're not as strong as 100% solids epoxy, which is what the pros often use.

The main downside to epoxy is that it hates sunlight. UV rays will cause it to turn yellow and become chalky over time. That's why it's not great for outdoor use unless it's protected by a different kind of topcoat.

A Warning About "1-Part Epoxy"

You'll see products at the hardware store labeled "1-Part Epoxy" or "Epoxy-Acrylic." Be warned: these are not real epoxy coatings. They are just acrylic paint with a tiny amount of epoxy resin mixed in for marketing purposes.

They don’t have a separate hardener, so they don't have the chemical cross-linking reaction that gives true epoxy its strength. They are only slightly tougher than regular paint and will not hold up on a garage floor. Don't fall for the hype.

The Even Tougher Stuff: Poly-whatevers

This family of coatings is a step up from epoxy. They are often used as a topcoat over an epoxy base.

- Polyurethane: This is like a bodyguard for your epoxy floor. It’s more scratch-resistant than epoxy and, crucially, it's UV stable, so it won’t turn yellow in the sun. A common pro system is an epoxy color coat with a clear polyurethane topcoat.

- Polyaspartic: This is a newer, high-performance coating that's also UV stable, super durable, and very flexible. Its main advantage is that it cures incredibly fast, meaning a floor can often be installed in a single day.

Special Cases: Waterproofers and Flexible Coatings

For specific problems, you need special products. Elastomeric coatings are super thick and stretchy, almost like rubber. They're great for bridging small cracks and waterproofing exterior walls. Cementitious coatings are a mix of cement and polymers, which bond incredibly well to concrete and are used for serious waterproofing.

Quick Comparison Chart

| Coating Type | Toughness | UV Resistance | Flexibility | Difficulty | Best For... |

|---|---|---|---|---|---|

| Acrylic / Latex Paint | Low | Good | Good | Easy | Basement walls, patios, porches (light use) |

| "1-Part Epoxy" | Low-Medium | Good | Good | Easy | Basement floors (no cars), light-traffic areas |

| 2-Part Epoxy | Excellent | Poor (will yellow) | Low (very rigid) | Medium | Garage floors, workshops, commercial spaces |

| Polyurethane | Excellent | Excellent | Medium | Medium | Topcoat over epoxy, high-traffic areas, outdoor use |

| Polyaspartic | Superior | Excellent | Excellent | Hard | Pro garage floors, fast-cure projects |

| Concrete Stain | Low (needs a sealer) | Good (with sealer) | N/A | Easy-Medium | Decorative floors, walkways, patios (for looks) |

| Elastomeric Coating | Medium | Good | Superior (stretchy) | Medium | Exterior walls, waterproofing, bridging cracks |

The Boring (But Crucial) Prep Work

Here's the most important secret to painting concrete: the prep work matters more than the paint. Seriously. Over 80% of coating failures are actually preparation failures. Skipping these steps is a guarantee that your project will fail.

Step 1: Clean Everything

First, get rid of anything that could get in the way of the paint's bond. Sweep or vacuum up all the loose dust and dirt.

Next, attack any oil or grease stains. Concrete soaks this stuff up, and paint won't stick to it. Use a concrete degreaser, scrub hard with a stiff brush, and rinse thoroughly. You might have to do this a few times for stubborn stains. If there’s old, peeling paint, you have to get it all off with scrapers or grinders.

Step 2: Fix the Cracks and Holes

A new coat of paint won’t fix bad concrete. You need to repair any cracks, pits, or flaking areas first. For small hairline cracks, a flexible masonry caulk will do the trick.

For wider cracks, you need a stronger filler, like a two-part epoxy or a cement patch. After your patches have fully cured, grind them down so they are perfectly smooth and level with the rest of the floor. Any bumps will show right through the final coat.

Step 3: Check for Moisture

This is the step everyone skips, and it’s the number one cause of failed floors. Before you even think about coating, test for moisture.

The easy DIY way is the plastic sheet test. Tape an 18x18-inch square of plastic sheeting to the floor, sealing all four edges. Leave it for 24 hours. If the underside of the plastic is wet or the concrete looks darker when you pull it up, you have too much moisture. Do not apply a coating until you fix the source of the water.

Step 4: Rough It Up a Bit

For paint to stick, it needs something to grab onto. A perfectly smooth, slick floor is a recipe for peeling. You need to create a texture, or "profile," on the surface that feels like medium-grit sandpaper.

The best way to do this is with mechanical grinding. You can rent a concrete grinder that uses diamond discs to rough up the surface perfectly. This is the method the pros use. It’s effective, predictable, and doesn’t add any moisture to the concrete.

The old-school DIY method is acid etching. This involves pouring a solution of muriatic acid on the floor to eat away at the top layer. The professional world agrees that this is an outdated, risky, and unreliable method. It’s dangerous, bad for the environment, and often doesn’t create a good enough profile for modern coatings. Just rent the grinder.

Step 5: Prime It

Finally, apply a primer. Primer is the bridge between the concrete and your topcoat. It seals the last of the concrete's porosity, ensures a uniform finish, and gives the paint a much stronger bond. Skipping primer is a classic mistake that leads to a weak, blotchy finish.

Pre-Paint Checklist

| Step | Task | Done? |

|---|---|---|

| 1: Clean | [ ] Sweep and vacuum all dust. | |

| [ ] Degrease all oil and grease spots. | ||

| [ ] Scrape/remove all old, peeling paint. | ||

| [ ] Rinse the surface and let it dry completely. | ||

| 2: Repair | [ ] Fill all cracks and holes. | |

| [ ] Grind all patches smooth and level. | ||

| 3: Moisture Test | [ ] Perform the plastic sheet test for 24 hours. | |

| [ ] Result: The concrete is dry. (PASS/FAIL) | ||

| 4: Profile | [ ] Mechanically grind the floor to a sandpaper-like texture. | |

| [ ] Vacuum all grinding dust. | ||

| 5: Prime | [ ] Apply a primer that's compatible with your topcoat. |

Time to Paint: The Fun Part

Once the prep is done, you can finally start making things look good. But even here, technique matters. A little planning and the right tools will save you from a lot of headaches.

Get the Right Gear

Use a good quality brush for cutting in along the edges. For the main floor, a roller is your best bet. A 3/8-inch nap roller cover works well for most smooth floors.

If you're using a two-part epoxy, you absolutely must mix it with a drill and a paddle mixer. Stirring by hand won't mix it properly, and it won't cure right. And if you're spreading decorative flakes, get yourself some spiked shoes so you can walk on the wet coating.

How to Avoid Ugly Lap Marks

The most common painting mistake is creating "lap marks," those ugly stripes where your roller passes overlap. This happens when you paint over an edge that has already started to dry. The secret to avoiding them is to always maintain a "wet edge."

This just means you should always paint from a dry area back into the wet paint you just put down. Work in small, manageable sections (like 4x4 feet) and finish an entire section without stopping. Only take breaks at natural stopping points, like a corner or a doorway.

Drying vs. Curing (Yes, There's a Difference)

These two words are not the same thing, and it’s important to know why.

- Dry-to-Touch: This is when the solvent has evaporated enough that the paint isn't tacky anymore. The coating is still very soft and easily damaged at this stage.

- Recoat Window: This is the specific time frame your product's instructions give you for applying a second coat. Too soon, and you'll trap moisture. Too late, and the next coat might not bond well.

- Full Cure: This is when the coating reaches its final hardness and chemical resistance. For a garage floor epoxy, it might be ready for light foot traffic in 24 hours, but it needs a full 7 days before it's strong enough to handle a car. Be patient!

Adding Decorative Flakes

Vinyl flakes are a great way to get a granite-like look and hide small imperfections. You have to broadcast them into the epoxy while it's still completely wet.

The best technique is to toss them up into the air and let them fall randomly onto the surface. Don’t throw them straight down, or they’ll clump up. After the floor has cured enough to walk on, you'll scrape off the loose flakes and vacuum them up before applying your final clear topcoat.

Making It Less Slippery

A glossy floor can be a skating rink, especially when wet. To add some grip, you can mix an anti-slip additive into your final topcoat. These are usually fine particles of polymer grit or aluminum oxide.

Just mix the grit into your clear topcoat right before you apply it. Stir it occasionally as you work to keep the particles from settling to the bottom of your paint tray.

Why You Need a Clear Topcoat

A clear topcoat isn't just for shine, it's a critical part of a high-performance floor system. It acts as a sacrificial layer that takes all the scratches and wear, protecting the color coat underneath.

Most importantly, if you're using epoxy, a UV-stable topcoat like polyurethane is essential to stop it from turning yellow in the sun. It also makes the floor much easier to clean and gives the color a richer, deeper look.

Keeping It Pretty & Fixing Your Mistakes

You've done all the work, now you have to take care of it. A little regular maintenance will keep your floor looking great for years. And if things go wrong, it helps to know why.

How to Clean Your New Floor

The biggest enemy of your new floor is grit, the sand and dirt that act like sandpaper under your shoes. Sweep or dust mop it regularly.

For wet cleaning, use a simple pH-neutral cleaner, even a mild dish soap in warm water works fine. Avoid harsh chemicals like bleach, ammonia, or vinegar, which can damage the coating. Wipe up spills like oil or gasoline quickly.

Troubleshooting Common Screw-Ups

-

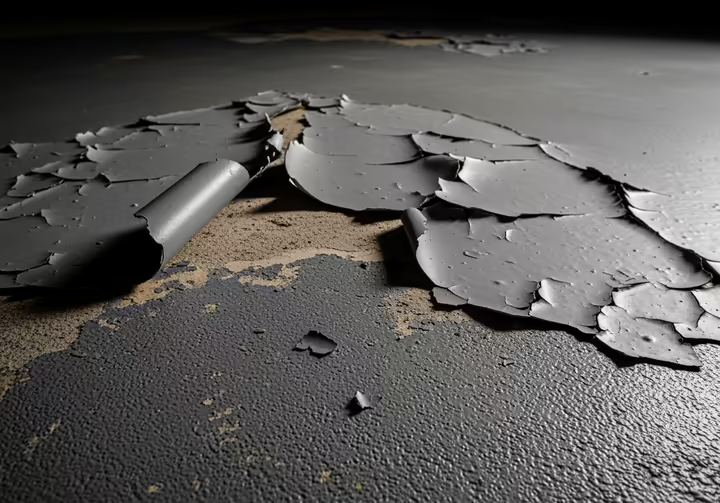

Problem: The paint is peeling off in big sheets.

This is almost always a prep failure. You either painted over a dirty, oily surface, or the concrete was too smooth and the paint had nothing to grab onto. The only fix is to strip it all off and start over, doing the prep right this time. -

Problem: There are bubbles or blisters under the paint.

This is a moisture problem, plain and simple. Water vapor coming up through the concrete got trapped under the coating and pushed it up. You skipped the moisture test. -

Problem: My car tires are pulling the paint off.

This is called "hot tire pickup." It happens for two reasons: you used a cheap, low-quality coating (like a "1-Part Epoxy"), or you parked on a high-quality coating before it had fully cured for 7 days. -

Problem: The color is faded and looks chalky.

This is UV damage. You used an epoxy coating in an area that gets sunlight, and you didn't protect it with a UV-stable topcoat like polyurethane.

Fixing Scratches and Worn-Out Spots

For small chips or scratches, you can do a spot repair. Sand the damaged area, clean it, prime it, and re-coat it, trying to blend it with the surrounding floor.

If the floor is just looking dull after years of use, you can bring it back to life. Just give the whole surface a light sanding (or "scuff"), clean it well, and apply a fresh clear topcoat. It'll look brand new again.

Don't Hurt Yourself (Seriously)

Working with this stuff involves real hazards, from toxic dust to chemical fumes. Take safety seriously and wear the right Personal Protective Equipment (PPE) for each step.

Your Safety Shopping List (PPE)

- When Grinding: Concrete dust contains silica, which is terrible for your lungs. You need a NIOSH-approved respirator with P100 filters (a paper dust mask is not enough) and sealed safety goggles.

- When Using Acid: Acid can cause severe chemical burns. Wear chemical splash goggles, acid-resistant gloves, and a respirator with acid gas cartridges.

- When Applying Coatings: Solvent-based coatings release harmful fumes (VOCs). Work in a well-ventilated area and wear a respirator with organic vapor cartridges. Always wear chemical-resistant gloves.

Ventilation is Your Friend

When working indoors, you need more than just an open window. Create a cross-breeze. Use one fan to push fresh air in and another fan in an opening on the opposite side to pull the contaminated air out.

A Special Warning About Acid

If you ignore our advice and use muriatic acid anyway, you need to be extremely careful. Remember the rule: Always Add Acid to Water. Never the other way around. Adding water to acid can cause a violent reaction that splashes corrosive acid everywhere.

When you're done, you must neutralize the acidic runoff with a base like baking soda before you can dispose of it. Take it to a hazardous waste facility, don't just pour it down the drain.

What to Wear for Each Job

| Task | Primary Hazard | Eyes | Skin | Lungs |

|---|---|---|---|---|

| Concrete Grinding | Silica Dust | Sealed Goggles | Gloves, Long Sleeves | P100 Respirator |

| Acid Etching | Chemical Splashes, Fumes | Chemical Splash Goggles | Acid-Resistant Gloves & Apron | Acid Gas Respirator |

| Applying Water-Based Paint | Minor Splashes | Safety Glasses | Gloves (optional) | None |

| Applying 2-Part Coatings | VOC Fumes, Skin Contact | Safety Glasses/Goggles | Chemical-Resistant Gloves | Organic Vapor Respirator |

Works cited

- The Challenges of Painting Concrete Block - Anderson Painting NC, https://www.andersonpaintingnc.com/blog/the-challenges-of-painting-concrete-block

- Why Can't I Just Use Standard Paint On Concrete? – TA Paints, https://www.taindustrialpaints.co.uk/blogs/blog/why-cant-i-just-use-standard-paint-on-concrete

- What You Must Know About Concrete - Prime Coat, https://primecoat.com/what-you-must-know-about-concrete/

- MOISTURE PROBLEMS:ANTICIPATION, TREATMENT AND REMEDIATION - Sweets Construction, https://sweets.construction.com/swts_content_files/567/372999.pdf

- About Concrete Moisture & Alkalinity, http://gsgdistribution.com/concrete-moisture-alkalinity/

- The 6 Biggest Problems With Concrete Floor Paint, https://www.taindustrialpaints.co.uk/blogs/blog/the-6-biggest-problems-with-concrete-floor-paint

- The problems of painting over concrete and cement mortar - NRC Publications Archive, https://nrc-publications.canada.ca/fra/voir/td/?id=41c6dfcf-6189-400f-af45-90aff49875ae

- How to Paint Concrete in 5 Easy Steps - The Spruce, https://www.thespruce.com/how-to-paint-concrete-7567737

- Curing New Concrete | Pro Tip - Harris Paints, https://championsofcolour.com/pages/pro-tip-curing-new-concrete

- How to Fix Alkali Burning & Discoloration | Sherwin-Williams, https://www.sherwin-williams.com/en-us/project-center/maintenance-repair/how-to-fix-alkali-burning-discoloration

- Alkali Resistance - Burning / Discoloration - Sherwin-Williams, https://www.sherwin-williams.com/painting-contractors/products/resources/SW-ARTICLE-PRO-ALKALIBURN

- What are different types of industrial floor coatings? | Duraamen, https://duraamen.com/blog/concrete_coatings/

- Why New Coatings Fail on Old Concrete Floors - KTA-Tator, Inc., https://kta.com/coatings-fail-old-concrete-floors/

- Why Flooring Professionals Must Always Test For Excessive Moisture And Alkalinity, https://www.moisturemeters.com/why-flooring-professionals-must-always-test-for-excessive-moisture-and-alkalinity/

- Most Common Concrete Coating Problems: How Floor Shield Helps, https://floorshieldcoatings.com/blog/most-common-concrete-coating-problems-how-floor-shield-helps

- Is 12 hrs dry time long enough for my concrete to get rained on tonight or does in need to be covered. It was like 80° here all day if that helps - Reddit, https://www.reddit.com/r/Concrete/comments/zenvqp/is_12_hrs_dry_time_long_enough_for_my_concrete_to/

- Efflorescence - How to Fix Paint Efforescence | Dulux, https://www.duluxtrade.com.au/technical-advice/performance/efflorescence/

- How To Paint Over Efflorescence - Rawlins Paints Blog, https://www.rawlinspaints.com/blog/how-to-paint-over-efflorescence/

- Efflorescence: What Are the Problems With it - Damp Solutions, https://www.damp-solutions.com/blog/efflorescence-what-are-the-problems-with-it/

- Efflorescence back immediately after painting over? : r/HomeImprovement - Reddit, https://www.reddit.com/r/HomeImprovement/comments/122niob/efflorescence_back_immediately_after_painting_over/

- How to Select the Best Concrete Paint or Stain - Lowe's, https://www.lowes.com/n/buying-guide/exterior-concrete-paint-stain

- Latex vs. Acrylic Paint for Tampa Bay Homes: Which Is Better?, https://www.fivestarpainting.com/blog/2023/september/latex-vs-acrylic-paint/

- The Essential Guide to Elastomeric Coatings for Concrete - Everlast ..., https://everlastconcretefloor.com/blog/elastomeric-coatings-for-concrete/

- Concrete Staining vs. Acid Staining vs. Epoxy Coating - Mile High Coatings, https://milehighcoatings.com/concrete-staining-acid-epoxy-coating/

- Should You Epoxy Or Stain Your Concrete?, https://utahconcretecoating.com/should-you-epoxy-or-stain-your-concrete/

- Concrete Sealer vs. Epoxy Coating: The Difference | E-Chem, https://e-chem.net/blog/concrete-sealer-vs-epoxy-coating-the-difference/

- Understanding The Different Types of Concrete Coatings | Concrete ..., https://concretecoatingsmn.com/understanding-the-different-types-of-concrete-coatings/

- Latex Paint - Design Life-Cycle, http://www.designlife-cycle.com/latex-paint

- The Acrylic vs Latex Paint Guide: Which Should You Choose? - Boise Home Painting, https://boisehomepainting.com/blog/acrylic-vs-latex-paint-guide/

- Acrylic vs. Latex Paint: Which Should You Choose? | Angi, https://www.angi.com/articles/types-of-paints-latex-vs-acrylic.htm

- Latex (Acrylic) Paint - Endeavour Centre, https://endeavourcentre.org/resources-for-building-green/free-encyclopedia-of-sustainable-building-materials/finishes/latex-acrylic-paint/

- www.designlife-cycle.com, http://www.designlife-cycle.com/latex-paint#:~:text=There%20are%20a%20large%20number,chemicals%20used%20in%20the%20process.

- US6930143B2 - Acrylic latex composition - Google Patents, https://patents.google.com/patent/US6930143B2/en

- Best Outdoor Paint for Concrete and Patios - The Home Depot, https://www.homedepot.com/c/ab/best-outdoor-paint-for-concrete-and-patios/9ba683603be9fa5395fab9088b3c1e9

- Latex vs. Acrylic Paint: Which Is Best For Your Project?, https://www.columbiapaintco.com/paint/latex-vs-acrylic-paint-which-is-best-for-your-project/

- The 8 Best Concrete Paints of 2025 - The Spruce, https://www.thespruce.com/best-concrete-paints-11728696

- Best Garage Floor Coatings (2025) - This Old House, https://www.thisoldhouse.com/garages/best-garage-floor-coating

- Epoxy Coatings Guide | Sherwin-Williams Industrial Coatings, https://industrial.sherwin-williams.com/content/dam/pcg/sherwin-williams/protective-marine/na/us/en-us/pdfs/marketing-uploads/Protective-Epoxy-Coatings-Guide-Sherwin-Williams.pdf

- US20090065143A1 - Two-component epoxy adhesive composition - Google Patents, https://patents.google.com/patent/US20090065143A1/en

- US8053031B2 - Two-part epoxy composition - Google Patents, https://patents.google.com/patent/US8053031B2/en

- Elevate Your Garage with Premium Floor Coatings, https://www.garageflooringllc.com/garage-floor-coatings/

- SHIELD-CRETE® WATER-BASED EPOXY GARAGE FLOOR COATING - H&C Concrete, https://www.hcconcrete.com/product/shield-crete-water-based-epoxy-garage-floor-coating/

- 2 Part Epoxy Garage Floor Coating Kit | Supreme Paints & Coatings, https://supremepaintsandcoatings.com/products/1-epoxy-zenith-2-part-epoxy-floor-coating-1-1-mix-2-gallon-kit

- 3 Common Issues With Concrete Coatings (Causes and Effects) - Southwest Exteriors, https://www.southwestexteriors.com/blog/2023/august/3-common-issues-with-concrete-coatings-causes-an/

- Best 10 Basement Concrete Floor Paints - Onfloor Technologies, https://blog.onfloor.com/basement-concrete-floor-paints

- All About Polyurethane Coatings - Doxu Chemical, https://doxuchem.com/all-about-polyurethane-coating/

- Polyurethane - Wikipedia, https://en.wikipedia.org/wiki/Polyurethane

- Do You Need to Repair Concrete Cracks Before Coating? Here's What You Need to Know, https://floortechconcretecoatings.com/repair-concrete-cracks-before-coating/

- Why Your Waterproofing System Should Be Elastomeric, https://www.waterproofmag.com/2022/05/why-your-waterproofing-system-should-be-elastomeric/

- Elastomeric Sealants and Coatings for Resilient Surfaces - Clean-Coat, https://www.clean-coat.com/elastomeric-sealants-coatings/

- Cementitious waterproof coatings - BASF, https://www.basf.com/us/en/products/General-Business-Topics/dispersions/Industries/construction2/building-envelope/waterproofing/cementitious-waterproof-coatings-

- Ultimate Guide To Concrete Cement Paint: Types, Tips, And ..., https://coatingsdirectory.com/blog/guide-to-concrete-cement-paint-types-tips-and-lifespan/

- CEMENT PAINTS - DCMSME, https://www.dcmsme.gov.in/publications/pmryprof/chem/ch10.pdf

- What are cementitious polymers and where to use them? - Barefoot Concrete, https://barefootconcrete.com.au/what-are-cementitious-polymers-and-where-to-use-them/

- How to Prepare Concrete for Painting: 7 Critical Steps - Drylok, https://www.drylok.com/learn/blog/how-to-prepare-concrete-for-painting

- How I prep a concrete garage floor for painting? - Home Improvement Stack Exchange, https://diy.stackexchange.com/questions/173132/how-i-prep-a-concrete-garage-floor-for-painting

- How to Clean a Garage Floor Before Coating - YouTube, https://www.youtube.com/watch?v=rS8IbGJ325M&pp=0gcJCf0Ao7VqN5tD

- Painting a Garage Floor: Part 3 Degreasing the Floor - YouTube, https://www.youtube.com/watch?v=3NBonyhX5dg

- MAINTENANCE OF PAINTED CONCRETE FLOORS - Dulux Protective Coatings, https://www.duluxprotectivecoatings.com.au/media/1580/415_maintenance_of_painted_concrete_floors.pdf

- nutech.com.au, https://nutech.com.au/preparing-concrete-for-painting/#:~:text=Use%20the%20watering%20can%20to,the%20surface%20for%2015%20minutes.&text=After%2015%20minutes%2C%20high%20pressure,water%20pressure%20of%202000%20psi.&text=Allow%20the%20concrete%20surface%20to%20dry%20thoroughly.,-Step%206%3A%20Test

- How to Fix Cracks in Concrete - The Home Depot, https://www.homedepot.com/c/ah/how-to-fix-cracks-in-concrete/9ba683603be9fa5395fab90147c3431e

- Concrete Surfaces Crack Repair - Sherwin-Williams - YouTube, https://www.youtube.com/watch?v=oq23fmFM2kk

- Filling cracks in concrete floor prior to epoxy coat...what do i use? : r/DIY - Reddit, https://www.reddit.com/r/DIY/comments/77adae/filling_cracks_in_concrete_floor_prior_to_epoxy/

- How to Fix Spalling Concrete - Kirchner Building Centers, https://kirchnerbuildingcenters.com/blog/71558/how-to-fix-spalling-concrete

- Concrete Surfaces Spalling - Sherwin-Williams - YouTube, https://www.youtube.com/watch?v=Uj_BTrVhoIU

- Concrete moisture testing and mitigation - AMPP, https://www.ampp.org/resources/what-is-corrosion/concrete-moisture-testing-and-mitigation

- 3 Ways to Test Concrete Moisture - Tnemec Company, Inc., https://tnemec.com/remedy-index-page/3-ways-test-concrete-moisture/

- Tools and Techniques for Measuring Coating/Moisture Quality- Pt 2 - KTA-Tator, Inc., https://kta.com/measuring-coating-quality-moisture-pt-2/

- www.ampp.org, https://www.ampp.org/resources/what-is-corrosion/concrete-moisture-testing-and-mitigation#:~:text=ASTM%20D4263%20%E2%80%93%20Indicating%20Moisture%20in,the%20concrete%20indicates%20excessive%20moisture.

- How to Determine the Moisture Content of Concrete Prior to ..., https://www.pecora.com/how-to-determine-the-moisture-content-of-concrete-prior-to-applying-a-sealant-or-coating-material/

- How to Conduct a Garage Floor Moisture Test - YouTube, https://www.youtube.com/watch?v=21RqxMbFFWM

- Acid Etch or Grind Which Is Better? | Epoxy Plus LLC, https://www.epoxyplus.com/nl/blogs/news/acid-etch-or-grind-which-is-better

- Mechanical Surface Preparation vs. Acid Etching: Which is Best?, https://xtremepolishingsystems.com/blogs/decorative-concrete-and-epoxy-blog/the-future-of-concrete-surface-prep-mechanical-methods-outperform-acid-etching

- New construction home, do I need to do anything before the acid etch? : r/epoxy - Reddit, https://www.reddit.com/r/epoxy/comments/1fi3zoj/new_construction_home_do_i_need_to_do_anything/

- Should I Acid Etch or Grind My Garage Floor? | White Rabbit | De-clutter, https://www.whiterabbitinc.com/post/should-i-acid-etch-or-grind-my-garage-floor

- Grinding vs. Acid Etching Your Concrete Floor - Armorpoxy Inc, https://armorpoxy.com/grinding-vs-acid-etching-your-floor

- Grind, Shotblast, or Acid Etch: The Truth About Floor Prep Methods - Polzin Epoxy Designs, https://www.polzindesigns.com/2025/06/19/grind-shotblast-or-acid-etch-the-truth-about-floor-prep-methods/

- Acid Etching Is No Longer Recommended as a Concrete Prep Method, https://industrial.sherwin-williams.com/na/us/en/resin-flooring/contractor-center/technical-articles/acid-etching-no-longer-recommended-concrete-prep-method.html

- How to Acid Etch Concrete Before Painting Tips | SANI-TRED, https://sanitred.com/how-to-acid-etch-concrete/

- Acid Washing Concrete: Risks & Safety Tips - Woodlands General Contracting, https://woodlandsgeneralcontracting.com/acid-washing-concrete-risks-amp-safety-tips/

- Avoid Lap Marks By Maintaining a "Wet Edge" | Benjamin Moore, https://www.benjaminmoore.com/en-us/contractors/job-solutions/troubleshooting/lap-marks

- Waterproof Primers That Help It Stick — and Stay Stuck - W. R. Meadows, https://www.wrmeadows.com/building-envelope/primers/

- Epoxy Coating For Garage Floors, https://armorgarage.com/shop-by-product/garage-epoxy-flooring/

- Step by Step: How to Install an Epoxy Flake Floor, https://www.concretefloorsupply.com/how-to-install-epoxy-flake-floor/

- armorpoxy.com, https://armorpoxy.com/how-to-apply-decorative-colored-flakes-evenly#:~:text=Hand%20Tossed,floor%20in%20an%20even%20manner.

- How To Apply Decorative Colored Flakes Evenly? - Armorpoxy Inc, https://armorpoxy.com/how-to-apply-decorative-colored-flakes-evenly

- Lapping - Sherwin-Williams, https://www.sherwin-williams.com/sw-article-pro-lapping

- How to Add Rust-Oleum Decorative Color Chips to Your Garage Floor Coating - YouTube, https://www.youtube.com/watch?v=XwoHNrXPvtA

- How to avoid lap lines and roller marks while applying concrete sealers? - Duraamen, https://duraamen.com/blog/concrete-sealer-application/

- Paint Drying and Curing: A Journey to Flawless Finish - SpecialChem, https://www.specialchem.com/coatings/guide/drying-and-curing

- Epoxyshield 240 oz. Gray High-Gloss, Low Voc 2-Part Epoxy Concrete Basement and Garage Floor Kit - The Home Depot, https://www.homedepot.com/p/Rust-Oleum-EpoxyShield-Epoxyshield-240-oz-Gray-High-Gloss-Low-Voc-2-Part-Epoxy-Concrete-Basement-and-Garage-Floor-Kit-365187/314107168

- How to Use Anti-Slip Additives for Epoxy Flooring - Canadian ..., https://canadianconcretesurfaces.ca/anti-slip-additives-for-epoxy-flooring/

- concreteexperts.ca, https://concreteexperts.ca/blog/how-to-use-anti-slip-additive-for-concrete/#:~:text=Using%20concrete%20paint%20to%20create,before%20applying%20the%20first%20layer.

- How to Apply Rust Oleum Anti skid Additive | Concrete Garage Floor Coating | Optional Step, https://www.youtube.com/watch?v=IVu-H8CbRDc

- Anti-Slip Floor Finish Additive | BEHR PREMIUM® | Behr Canada, https://www.behr.ca/consumer/products/floor-coatings-sealers-and-prep/floor-enhancements-and-additive/behr-premium-anti-slip-floor-finish-additive

- 10 Reasons you Should Add a Clear Top Coat to your Epoxy Floor, https://www.epoxyfloornow.com/post/2015/01/18/10-reasons-you-should-add-a-clear-top-coat-to-your-epoxy-floor

- Clear Coat Concrete Floor: Ultimate Protection and Shine Guide | Shark Coatings, https://sharkfloorcoatings.com/blog/clear-coat-concrete-floor-ultimate-protection-and-shine-guide/

- Concrete Clear Coat Guide: Application Tips & Long-Term Benefits - Rust Bullet, https://www.rustbullet.com/how-to-use-clear-coat-for-concrete-and-its-benefits/

- How to Clean Concrete Floors & What to Use | Concrete Floor Supply, https://www.concretefloorsupply.com/cleaning-concrete-floors/

- How to Clean a Stained Concrete Floor | Triad Service Solutions, https://triadservicesolutions.com/how-to-clean-a-stained-concrete-floor/

- Five Mistakes to Avoid When Painting Concrete Flooring - Anderson Painting NC, https://www.andersonpaintingnc.com/blog/5-mistakes-to-avoid-when-painting-concrete-flooring

- How to Fix Peeling Epoxy Coatings on Your Concrete Floor (Or Whether To Start Over), https://everlastconcretefloor.com/blog/how-to-fix-peeling-epoxy-coatings/

- Concrete Safety Gear Checklist, https://www.mcrsafety.com/blog/concrete-safety-gear-checklist/

- Shifting Towards a Culture of Safety in Concrete Coatings ..., https://desertpolymerflooring.com/resources/blog/shifting-towards-a-culture-of-safety-in-concrete-coatings-installation/

- Muriatic Acid - Top Tips for Safe Use in Cleaning - Bob Vila, https://www.bobvila.com/articles/muriatic-acid/

- etch / stain concrete | Pressure Washing Institute - XenForo, https://propowerwash.com/board/upload/threads/etch-stain-concrete.2669/

- How to Dispose of Muriatic Acid: 9 Safe Options - wikiHow, https://www.wikihow.com/Dispose-of-Muriatic-Acid

- How to Etch a Concrete Floor in 13 Steps? | DRYLOK, https://www.drylok.com/learn/blog/how-to-etch-concrete-floor

- Concrete Safety Gear Checklist - MCR Safety - B2B, https://www.mcrsafety.com/blog/concrete-safety-gear-checklist

- eTool : Shipyard Employment - General Requirements - Personal Protective Equipment (PPE) - PPE Selection - Painting | Occupational Safety and Health Administration, https://www.osha.gov/etools/shipyard/general-requirements/ppe/ppe-selection/painting

- Top Gun Garage on How Proper Ventilation Affects Epoxy Installation, https://topgun-garage.com/how-proper-ventilation-affects-epoxy-installation/

- Ventilation Guidance for Spray Polyurethane Foam Application | Safer Choice | US EPA, https://archive.epa.gov/epa/saferchoice/ventilation-guidance-spray-polyurethane-foam-application.html

- Etching concrete with muriatic acid - DoItYourself.com Community Forums, https://www.doityourself.com/forum/bricks-masonry-cinder-block-paving-walking-stones-asphalt-concrete/416508-etching-concrete-muriatic-acid.html

- HHW - Muriatic Acid - MCMUA, https://mcmua.com/sw_hhw_faq_muriatic_acid.asp